优势

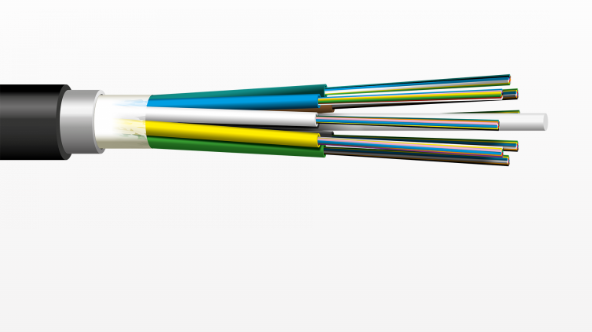

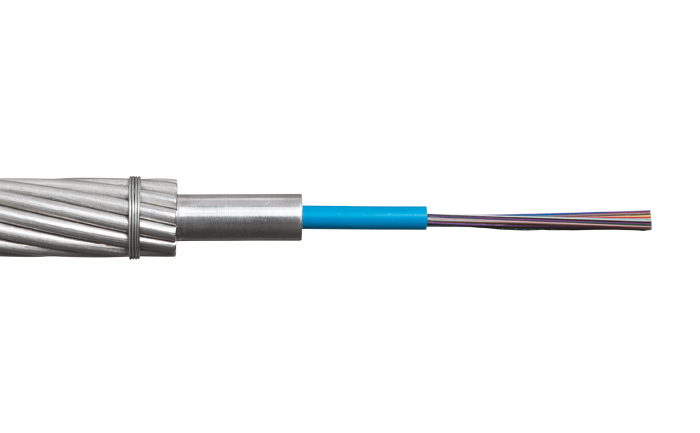

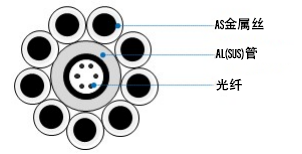

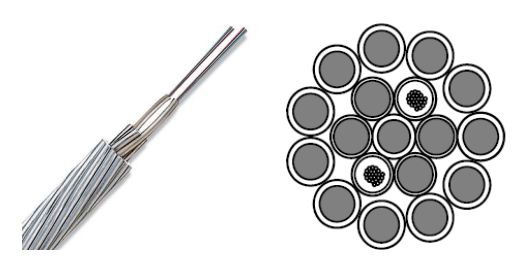

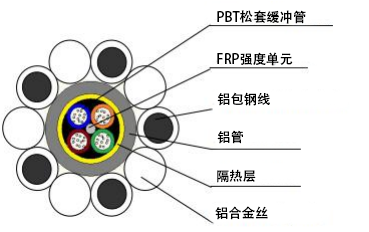

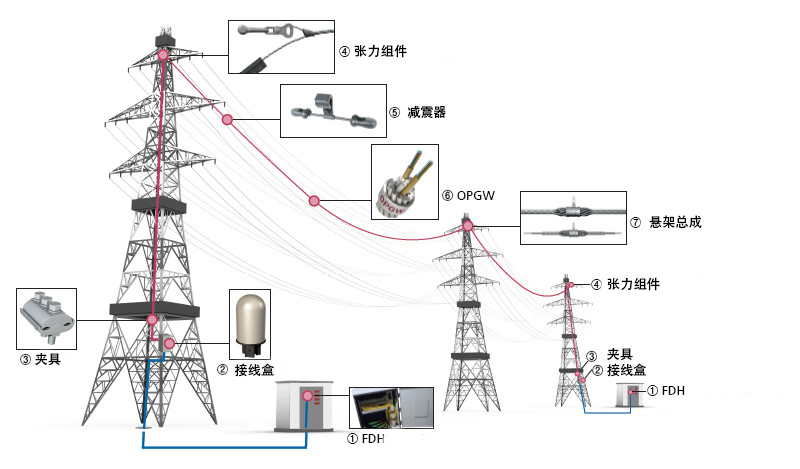

OPGW光缆具有传统屏蔽线的所有优点,例如提供短路接地路径和保护电路免受雷击,并且具有良好的紧凑性,此外还提供用于通信的光通路,高度稳定,高可靠性, 抗拉强度高,通信质量高,成本低,传输信号损耗小,抗电磁干扰,不易被盗窃,不易被破坏性攻击。

应用

OPGW光缆用于电力行业,输配电线路(即500KV、220KV、110KV电压等级线路)、语音、视频、数据传输、SCADA网络、阿里尔地线、暗光纤租赁。

总结

OPGW光缆在保持了架空地线的所有性能的同时,也为光纤通信网络开辟了道路,无需再增加一条挂线。 OPGW具有可靠性高、机械性能优越、成本低等显着优点。

位置 :

首页11

>产品资讯

位置 :

首页11

>产品资讯