Tips for Choosing the Right Fiber Optic Cable

1. Fiber Types

First, we should select single-mode (SM) or multi-mode (MM) fiber optic cable according to the network application and specification. Typically, SM fiber is used in long-distance and outdoor applications, and MM fiber is used in short-distance and indoor applications.

2. Fiber Counts

After we have selected the fiber type, we need to figure out how many fibers are required for the network construction. This depends a lot on the FTTX (Fiber-to- the-x) and ODN (optical distribution network ) scale and which part of the fiber optic cable is used.

A backbone fiber optic cable from the data center to the distribution cabinet can have fiber counts from 24 cores to 288 cores. Fiber counts for distribution fiber optic cable are like backbone fiber optic cable but normally fewer. And FTTH drop cable is normally 1 core or 2 cores.

3. Application Environment

The structure and material of the fiber optic cable should also be considered based on where the fiber optic cable is used.

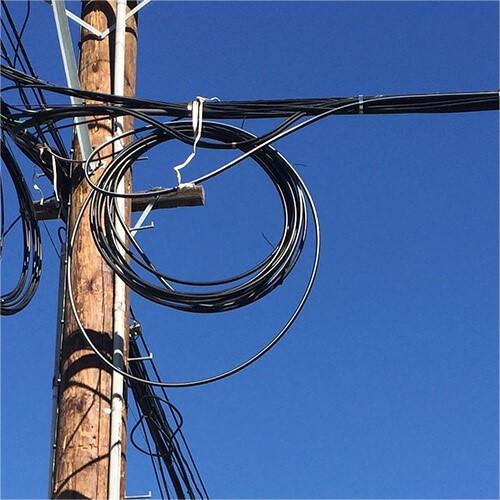

Outdoor

When it’s an outdoor application and cable needed to be directly buried, a loose tube-stranded armored fiber optic cable is the best choice. This cable provides crush protection for optical fiber and the cable itself.

When it’s an aerial construction, a fiber cable that can support its weight is a better one. A self-supporting fiber optic cable has strength members such as an extra steel wire or FRP messenger or aramid yarn to provide performance on tensile. The most common self-supporting fiber optic cable structures are figure 8 and ADSS.

Indoor

Cable characteristics of flame retardant, low smoke, and halogen-free (LSZH) should be the first thing we need to pay attention to when the cable is used indoors. Normally, we can check this from the class of cable flame retardant and sheath material like LSZH.

In pipeline places, flame retardant (FR), and the smoke-free or combustible non-toxic type (LSZH) are good solutions. In an exposed indoor environment, a fiber cable of flame retardant, non-toxic, and smokeless type (riser cable) is required.

A tight buffer fiber also provides good mechanical performance such as a small bend diameter, soft and easy to strip for indoor application.

Building

When laying cables vertically or horizontally in the building, it is recommendable to select tight buffer fiber cables, distribution cables, or branch optical cables.

4. Connectors

The connector plays a key role in establishing a secure fiber network. The main types of connectors include ST, FC, SC, LC, and MTP. The ST (straight tip) connector is the most popular connector in MM networks. It’s spring-loaded, which means it can be easily connected and removed.FC (ferrule connector) has a threaded body and is mainly used in high-vibration environments, polarized optical fibers, and SM fibers. The SC (subscriber connector) is a snap-in connector that latches with a simple push-pull motion. It’s mainly used in SM fiber, duplex networks, CATV, media converters, and FTTX. LC (Lucent connector) is a standard ceramic ferrule connector that can be easily terminated with any adhesive, nearly half the size of the SC connector. It is mainly used for SM fiber, data centers, local networks, FTTH, CATV, etc. MTP (Multi-fiber termination push-on) connector is a registered trademark of US conec and provides a high-performance MPO connector designed for better optical and mechanical performance. It is used in data centers, broadcast communications, and industrial control applications.

Conclusion

So these have been a few of the several factors, which we need to consider when it comes to choosing the right fiber optic cables. Consider the tips in mind and pick the ones which are favorable for your applications. Sun Telecom provides a wide range of options for fiber optic cables to the global market. Contact us if you have any needs.

Position :

Home>

News & Tutorial

>Products

Position :

Home>

News & Tutorial

>Products

Position :

Home

>Products

Position :

Home

>Products

ics@suntelecom.cn

ics@suntelecom.cn  +86 18964888554

+86 18964888554 Building No.145, Lane 666 Xianing Road, Jinshan Industrial Zone, Shanghai 201506, China

Building No.145, Lane 666 Xianing Road, Jinshan Industrial Zone, Shanghai 201506, China