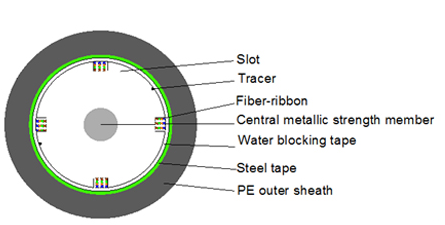

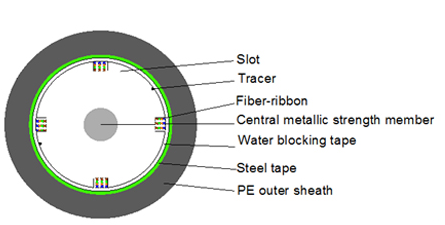

Structure

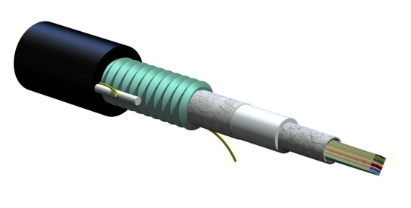

In ribbon cable structure, the fiber ribbons are housed in slots (with a metal central strength member) to form a cable core. The core is wrapped with water-blocking tape and armored with laminated steel tape, and then a PE outer sheath is extruded. With this special structure, ribbon cables allow mass-fusion splicing, with 12 fibers spliced in a single procedure for easier fiber management, faster network builds, and quicker restoration following fiber cable cuts.

Features and Benefits

The ribbon cable offers good mechanical and temperature performance, excellent crush resistance, high tensile strength ensured by steel wire, all-dry design, high fiber counts, high fiber density, high bandwidth, four times the highest-fiber-count loose tube cable, and mass fusion of fibers. Furthermore, the ribbon cable can offer efficiency and cost savings, better solutions to congested pathways and conduits, more closure flexibility, reduction of splicing error rates, quicker time to restoration, ease of management and installation, and improved OSP productivity.

Applications

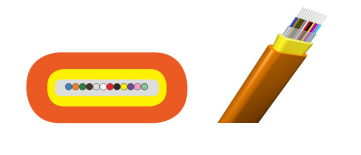

The ribbon cable is used in the data center, core network, metropolitan area network (MAN), local area network (LAN), avionics networks, ethernet backbone, indoor FTTH networks, indoor/outdoor point-to-point applications, interconnection and crossover applications of MTP optical fiber distribution boxes; the 12-core ribbon cable is the most widely used type of ribbon cables, and the 12-core ribbon cable can be easily used by SC and LC simplex connector, duplex connectors or MTP connector. In addition, the ribbon cable is used in digital video systems, flight management systems, weather radar systems, CATV, etc.

Conclusion

The ribbon cable is designed to offer the high fiber density possible relative to cable size with a highly flexible cable jacket that promotes ease of handling and installation to help speed deployment, durability, and enhanced compression resistance. Sun Telecom aims to provide ribbon cable products for the global market.

Position :

Home>

News & Tutorial

>Products

Position :

Home>

News & Tutorial

>Products

Position :

Home

>Products

Position :

Home

>Products

ics@suntelecom.cn

ics@suntelecom.cn  +86 18964888554

+86 18964888554 Building No.145, Lane 666 Xianing Road, Jinshan Industrial Zone, Shanghai 201506, China

Building No.145, Lane 666 Xianing Road, Jinshan Industrial Zone, Shanghai 201506, China